Drilling! With Kastner-Tools.

Micro precision-drills made of solid carbide for the production of holes between 0.5 mm and 3.0 mm with hole depths 3xD to 12xD. Available with both external shank cooling via six cooling channels and internal shank cooling via two twisted cooling channels. The standard drill tolerance of m7 enables the production of holes with a hole quality of H9 under normal conditions.

Thanks to the optimal interaction of finest carbide and a coating selection optimally adapted to the ISO material groups, the micro-precision drills from Kaestner-Tools offer highest performance, longevity and process reliability under almost any condition.

At one glance:

- Solid carbide micro precision drills for diameters from 0,5 mm to 3,0 mm

- Bore depths 3xD to 12xD

- precision tip grinding with optimized cutting edge geometry

- coating selection optimally adapted to ISO material groups

Two different coolant supply variants as standard:

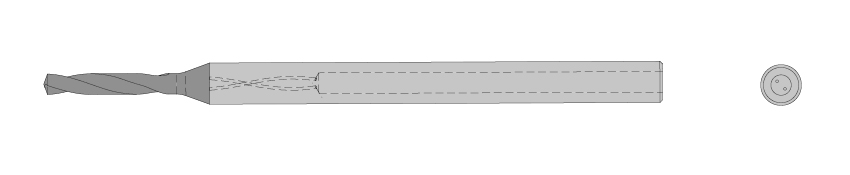

Shank cooling inside via two twisted cooling channels:

- Direct cooling at the cutting edge

- Reduces heat transfer into the material

- Ensures optimum chip removal and thus a high bore surface quality

- Optimized transport chamber in the shank for reliable coolant supply

- Active support of chip breaking by the coolant leads to increased process reliability

- Cooling channel diameters optimally adapted to the tool to enable both high tool stability and a high flow rate

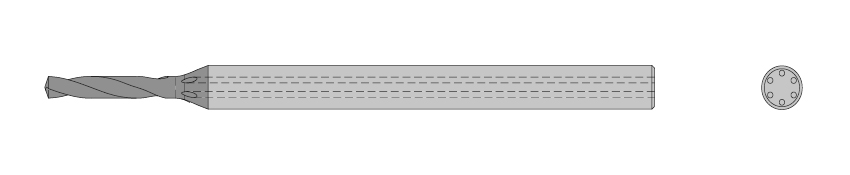

External shank cooling via six coolant channels:

- Direct cooling at the cutting edge

- Reduces heat transfer into the material

- Active support of chip breaking by the coolant leads to increased process reliability

- Complete stability of the tool is maintained

- Six cooling channels ensure a reliable supply of a sufficiently high amount of coolant to the cutting edges

For the use of our microprecision drills, we recommend a pilot bore upstream from a bore depth of 8xD.